What was the Idea?

I find the Geneva mechanism quite intriguing, so I thought it was time that I had a go with it myself. My initial idea was to make something like an inchworm or a cabbage looper, where the animal humps its back to bring up its rear legs and then stretches out to move its front legs forward. However, I was worried about the force required to lift up the body, so I went for a caterpillar that alternately stretches and contracts its body to move. A small passenger adds a little absurdity and I borrowed an idea from Lewis Carrol’s Alice in Wonderland where his caterpillar smoked a hookah. Mine smokes the portable version, a pipe.

The Geneva Mechanism

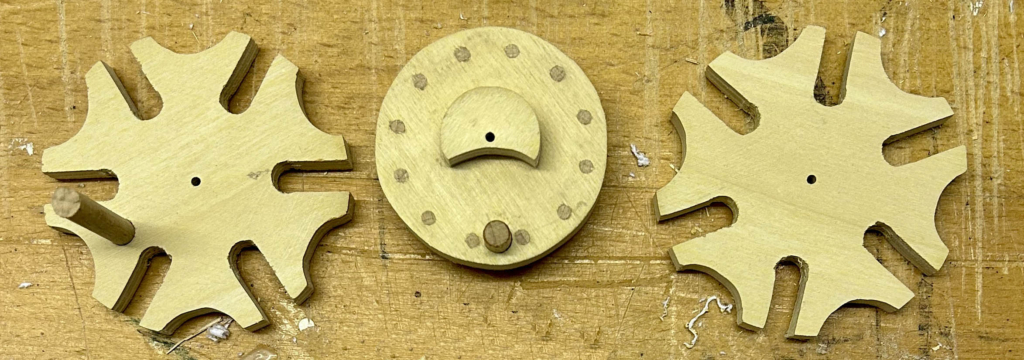

Searching the Internet, I found a marvellous Geneva Gear Generator https://benbrandt22.github.io/genevaGen/ which I used to produce a 6-way Geneva wheel design. From this, I made two wheels and the central driving element which is mounted onto the back of a pin gear with 12 pins.

The hand-turned axle drives another pin-wheel which engages with the central driving element. As the axle is turned the element rotates and turns the two Geneva wheels one after the other. Later on I found that misalignment occasionally occurred, jamming the movement. I fixed this by rounding off the corners where the round dowel on the driving element enters the long slots in the wheels.

To prevent friction from driving the wheels instead of the small piece of protruding dowel in the central element, the Geneva wheels must not rest on the central element, so I glued a wooden washer in place underneath each wheel allowing the wheels to turn freely when required.

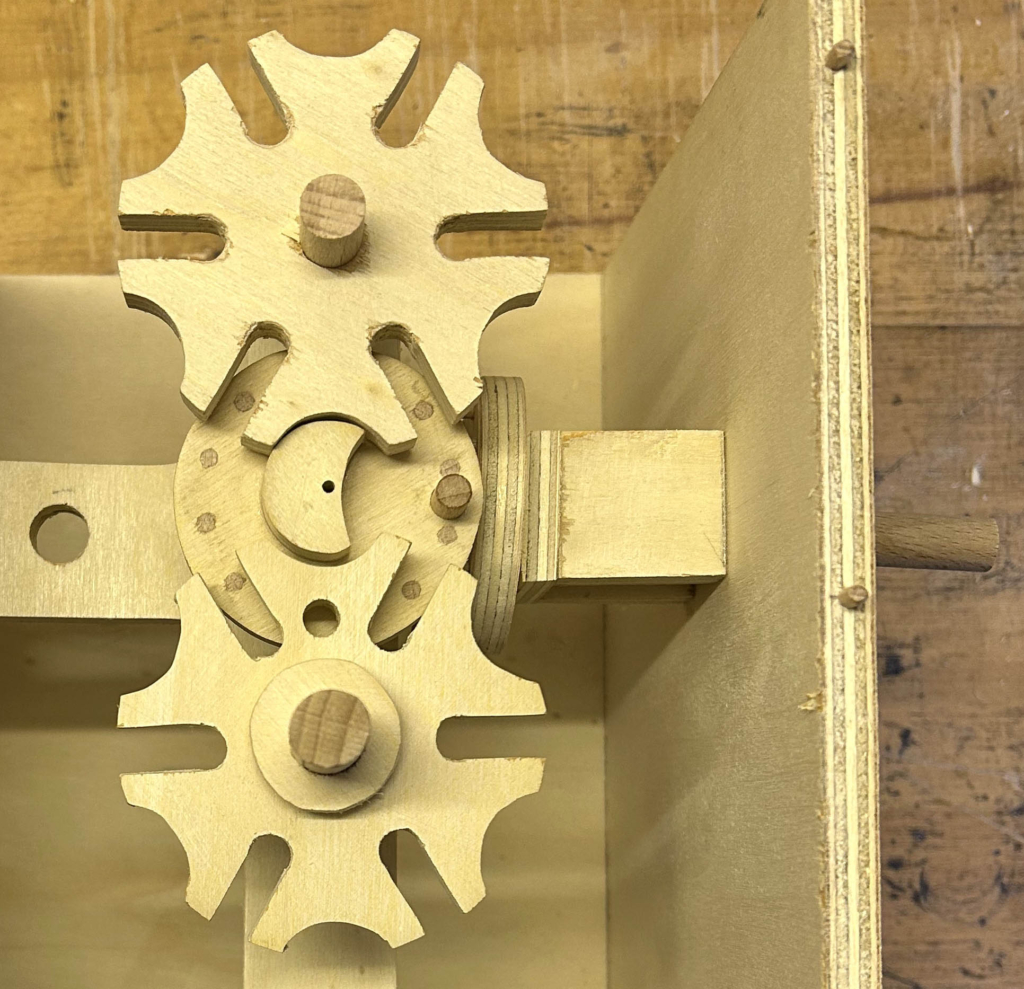

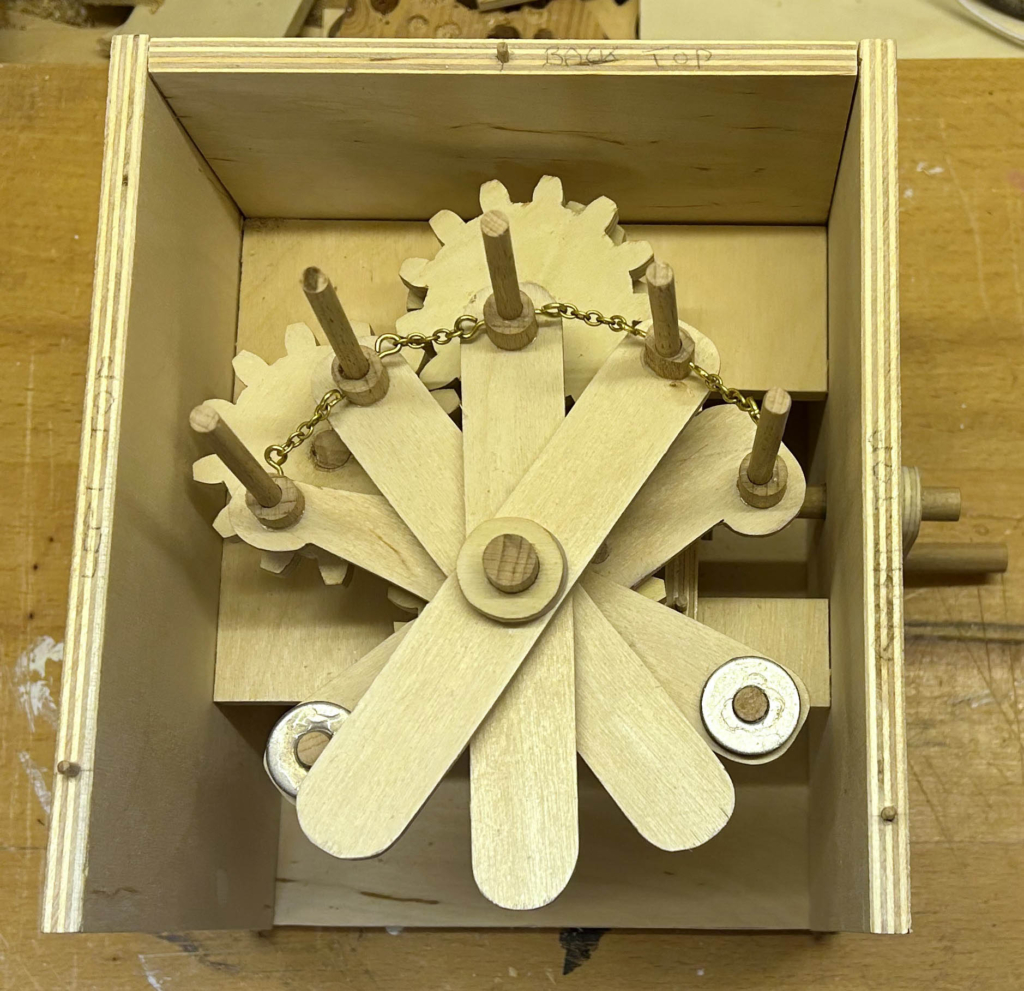

One Geneva wheel directly moves the front of the caterpillar via a piece of vertical dowel. The second wheel drives the caterpillar’s tail via three cogs and another piece of vertical dowel. I designed the cogs using another online tool https://woodgears.ca/gear_cutting/template.html.

The first cog is glued to the top of its Geneva wheel. The third cog turns freely above the other Geneva wheel, not touching it at all. This cog has an opening to allow the dowel from the Geneva wheel underneath it to freely move through an arc driving the front of the caterpillar, while it has its own dowel to drive the rear of the caterpillar. The second cog links the first and third together.

Extension Arms

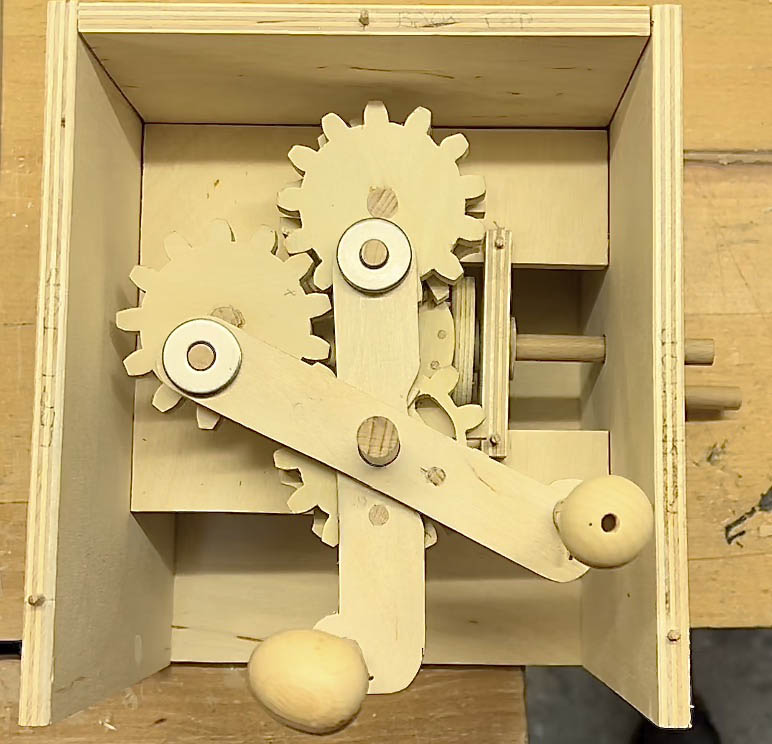

To enlarge the diameter of the caterpillar’s movement, extension arms are required. These also allow some counterbalancing to keep things horizontal.

With the caterpillar’s head and tail now alternately driven, there is a sort of scissoring action which first pulls the head away from the tail and then pushes the tail towards the head.

Three more arms are needed for the three segments between the head and the tail. The segments are linked together with a small piece of brass chain so that when the head moves it can pull the other segments along behind it.

A Ratchet

I didn’t want the caterpillar moving backwards, so I added a ratchet onto the drive shaft to prevent the crank from being turned the “wrong” way. Tightening the longer screw compresses the spring and makes things quite loud. I adjusted it until it did what I wanted without making too much of a racket.

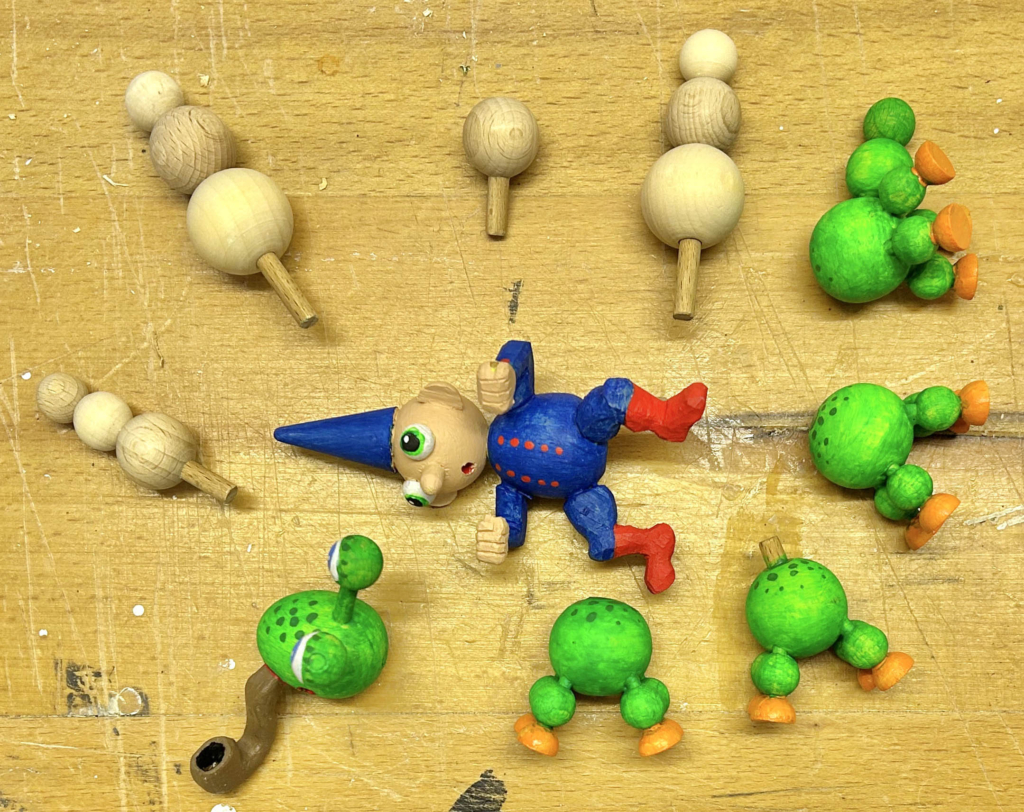

The Caterpillar Segments

The caterpillar segments mostly comprise wooden balls, with a wooden egg for the head. A few trees round off our small scene.

Making

This project is more complex than a lot of my automata, but there aren’t really that many parts to it. I used slightly thicker plywood than usual to improve rigidity and precision. During the first assembly, I noticed that my box was too small, so I made a new, larger one and took the opportunity to tidy things up a bit.

Note that the 10 mm diameter vertical dowel, which you can see in the photo, is fixed and glued in place. It represents the centre axle for the main mechanism. It does not move itself, the parts and the caterpillar move around it. When fully assembled the green disc is glued flush to its top.

Too Complicated?

Before I started, I looked around the Internet to see if anyone else had made a caterpillar automaton, I bumped into https://makerworld.com/de/models/468733#profileId-377949. This is a project for a 3D printer and, on the face of it, looks a lot simpler than mine. I don’t know whether it would work well, when made by hand in wood. What do you think?

Still, I am very pleased with how my project turned out, it works reliably and entertains my friends large and small. It took a while to make, but that’s part of the fun in making automata, overcoming difficulties and learning more every happy hour that I spend working with my hands.

Video

Youtube link https://youtu.be/cBHg6OAXFjw

Images

Download ZIP package from https://www.wordwise.de/Caterpillar_archive.zip